Ultimate 2.0 16v turbo build

Moderators: daewoomofo, Moderators Group

-

gse_turbo

- DTM Daewoo Mod

- Posts: 2394

- Joined: Fri Jun 23, 2006 4:20 am

- Location: Englewood, Colorado United States

- Contact:

Re: Ultimate 2.0 16v turbo build

I did get that PM. I'm gonna try and get cought up in my messages and emails by tomorrow. I apologize for the delay.

It's actually a de-stroker kit basically. I'm not a fan of stroker kits for inline fours, at least in FWD. The longer the stroke, the lower RPMs the peak torque comes in and it just spins tires.

It's actually a de-stroker kit basically. I'm not a fan of stroker kits for inline fours, at least in FWD. The longer the stroke, the lower RPMs the peak torque comes in and it just spins tires.

Re: Ultimate 2.0 16v turbo build

gse_turbo wrote:It's actually a de-stroker kit basically. I'm not a fan of stroker kits for inline fours, at least in FWD. The longer the stroke, the lower RPMs the peak torque comes in and it just spins tires.

Regarding building the water/air cooler into the intake manifold, I think thats a cool idea... but the one thing I wonder about is won't that water core be picking up lots of excess heat from the intake manifold itself? Typically the intake manifold is pretty warm/hot when the hood is closed/engine running for a while/hot day etc. It just seems like the engine heat would unnecessarily creep into the water core.. I guess you could use thick manifold spacers to help this somewhat.

Also if you are aiming for 600whp out of the 2.0L I hope you or someone you know is very experienced with tuning. At 300whp/L there is basically no tolerance for errors, even with a built motor.

2004 Optra/Forenza/Lacetti - 225whp - Haltech Sprint500 - CT12B - Getrag F28 6spd - KW V3 Coilovers - FX35 Retrofit

2002 IS300 5MT - 615whp - AEM EMS - GT4088R - Built 9.5CR - R154 - TRD LSD - SupraTT T/B - Varex - LS430 Retrofit

2002 IS300 5MT - 615whp - AEM EMS - GT4088R - Built 9.5CR - R154 - TRD LSD - SupraTT T/B - Varex - LS430 Retrofit

Re: Ultimate 2.0 16v turbo build

I'm curious about the intercooler myself but wanted to wait and see it. Not sure i fully understand the routing of it. An experience tuner is a definite must at that HP level. I'm excited to see this project reach that HP though.

Re: Ultimate 2.0 16v turbo build

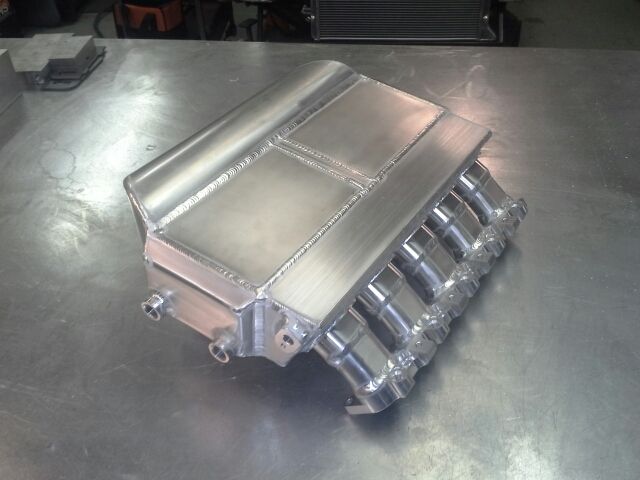

Ok so I just looked at a car in the shop that has a water to air in it. Are you essentially making the intercooler the intake manifold and adding runners to it? Will that be enough to cool the charge? I don't think heat soak would be a big issue because the water circulates through the manifold. Interested to see this design

-

gse_turbo

- DTM Daewoo Mod

- Posts: 2394

- Joined: Fri Jun 23, 2006 4:20 am

- Location: Englewood, Colorado United States

- Contact:

Re: Ultimate 2.0 16v turbo build

I like the activity so far on this thread. And great questions.

Jason, you pretty much answered the question for me. Right now I have paper-phanolic manifold spacers. I think it will work out just fine although fiber-phenolic might be better. The problem with any type of phenolic is that it puts off a toxic fume when it's machined and fiber-phenolic is pretty pricey.

Right now I'm looking into Teflon as an alternative. It tolerates heat well, it's safe to machine and it's generally cost effective. There are several different grades of Teflon so the hold up is choosing the one best suited.

I'm also considering having Cometic laser cut a thin stainless steel gasket to put between the head and Teflon spacer. The design advantage will be that I want to incorporate a heat shield that will isolate the intake from the motor.

The tune is certainly a major concern. I would like to reach the 600 mark but I imagine that I would drive it de-tuned or restricted to a lower number. Although more power is alway cool, I mostly want to reach that range just to say its possible with our motors.

Jason, you pretty much answered the question for me. Right now I have paper-phanolic manifold spacers. I think it will work out just fine although fiber-phenolic might be better. The problem with any type of phenolic is that it puts off a toxic fume when it's machined and fiber-phenolic is pretty pricey.

Right now I'm looking into Teflon as an alternative. It tolerates heat well, it's safe to machine and it's generally cost effective. There are several different grades of Teflon so the hold up is choosing the one best suited.

I'm also considering having Cometic laser cut a thin stainless steel gasket to put between the head and Teflon spacer. The design advantage will be that I want to incorporate a heat shield that will isolate the intake from the motor.

The tune is certainly a major concern. I would like to reach the 600 mark but I imagine that I would drive it de-tuned or restricted to a lower number. Although more power is alway cool, I mostly want to reach that range just to say its possible with our motors.

Re: Ultimate 2.0 16v turbo build

Manifold looks good. Pretty much what I was picturing. I'm curious though will condensation build up be an issue? Will there be a difference in air density from the first runner to the last?

-

gse_turbo

- DTM Daewoo Mod

- Posts: 2394

- Joined: Fri Jun 23, 2006 4:20 am

- Location: Englewood, Colorado United States

- Contact:

Re: Ultimate 2.0 16v turbo build

Here are pics of the oil pump gears.

This is the standard oil pump gear in majority of te 2.0 motors

This is the pump gear I the Z20LET/LEH.

This is the standard pump gear in the 1.6. It actually is a very good item.

This is the standard oil pump gear in majority of te 2.0 motors

This is the pump gear I the Z20LET/LEH.

This is the standard pump gear in the 1.6. It actually is a very good item.

Re: Ultimate 2.0 16v turbo build

Stock 1.6 oil pump gear looks good. Hopefully I won't face any issues with it.

- PrecisionBoost

- Super Moderator

- Posts: 4437

- Joined: Thu Jun 19, 2003 5:59 am

- Location: Edmonton, Alberta, Canada

Re: Ultimate 2.0 16v turbo build

600whp and higher has been done hundreds if not thousands of times in the Opel/Vauxhall 2.0L so I do not see why it should not be within reach with what you have planned.gse_turbo wrote: I would like to reach the 600 mark but I imagine that I would drive it de-tuned or restricted to a lower number. Although more power is alway cool, I mostly want to reach that range just to say its possible with our motors.

Sure it's 300hp/liter but your talking about a putting together a high revving engine, so your not going to need massive boost levels to achieve your goal.

Say you design everything to peak around 7500RPM, then that means you need 420lbft of torque.

I'm guessing your looking at 23psi to 25psi of boost to make that happen @ 7500 RPM

In my opinion your going to need to do some significant work on porting the cylinder head, installing larger valves, multi angle grind and perhaps a little shaving of the valve stem if you hope to get enough flow to support that level of power.

2010 BMW 335D

1994 Opel Calibra 4X4 turbo ( C20LET 2.0L Turbo )

2002 Daewoo lanos

1994 Opel Calibra 4X4 turbo ( C20LET 2.0L Turbo )

2002 Daewoo lanos

-

gse_turbo

- DTM Daewoo Mod

- Posts: 2394

- Joined: Fri Jun 23, 2006 4:20 am

- Location: Englewood, Colorado United States

- Contact:

Re: Ultimate 2.0 16v turbo build

This breif article was found at MotoIQ.com

Does Length Matter?

by Khiem Dinh

Khiem Dinh is an engineer for Honeywell Turbo Technologies at the time of this writing. All statements and opinions expressed by Khiem Dinh are solely those of Khiem Dinh and not reflective of Honeywell Turbo Technologies.

Someone recently asked, “Why a longer rod?” Someone else answered, “Longer dwell time.” I never really thought about it before, so I thought I’d look into it. Using some basic math, we can prove that a longer rod does indeed create a longer dwell time around top dead center.

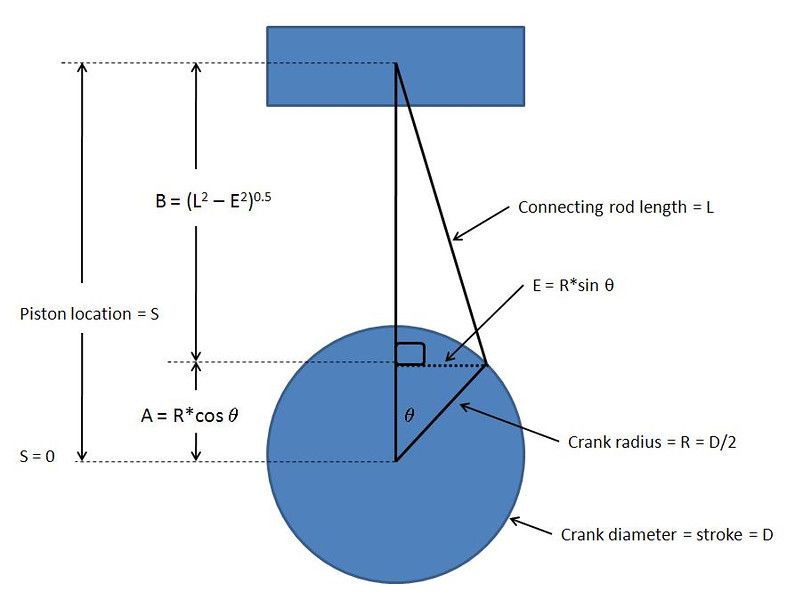

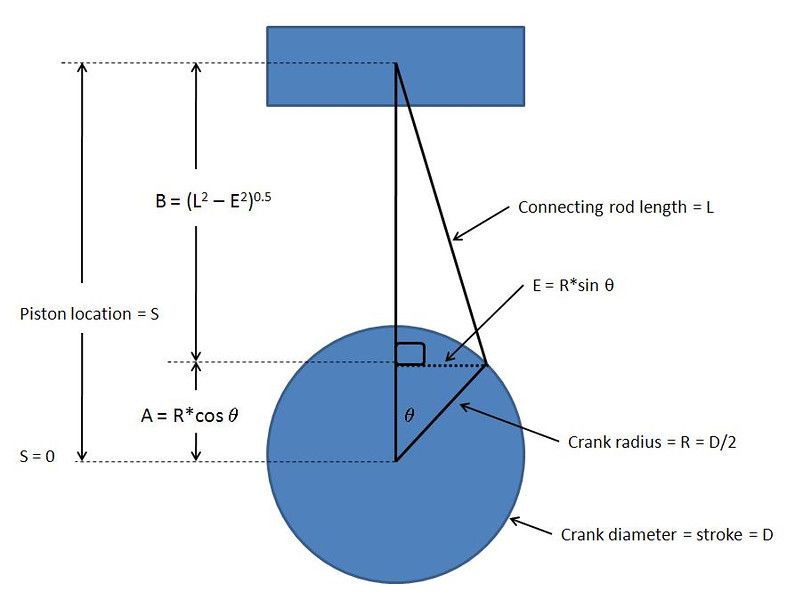

Here's a diagram showing the geometry between the crank, connecting rod, and piston. The math only works out assuming the piston pin location is not offset. So using some basic trig, we can calculate piston position (S =A+B in this diagram) versus crank angle.

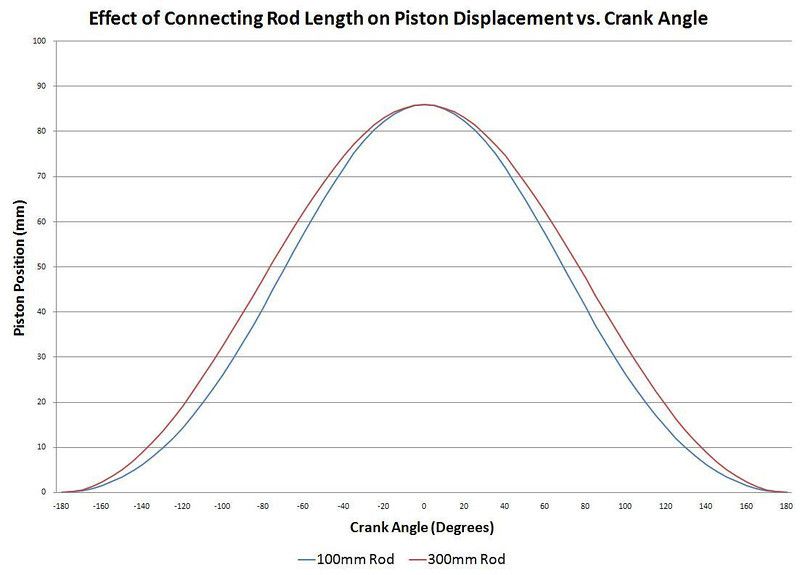

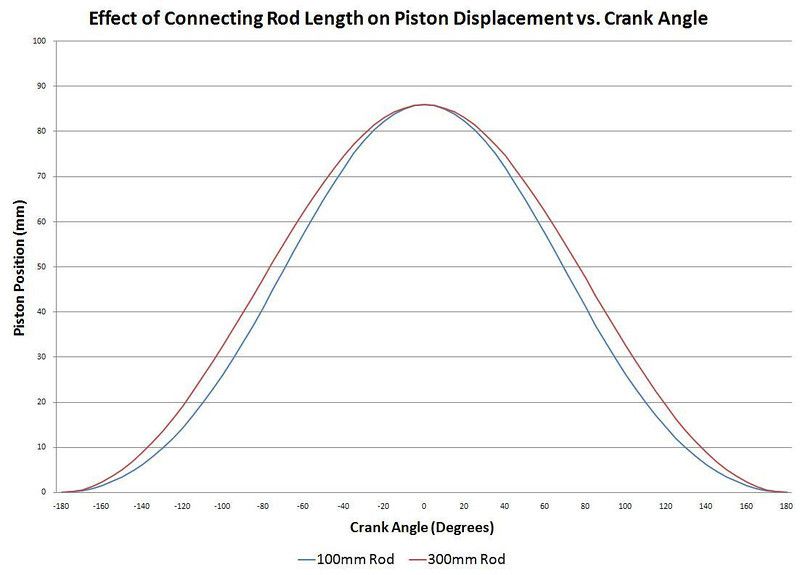

This graph shows piston position (normalized so that 0mm is BDC) vs. crank angle for 100mm and 300mm long connecting rods on an engine with an 86mm stroke. Yeah, you would never use a 300mm long conrod, but I wanted to make it easier to show the difference.

As you can see in the diagram, the piston with the longer conrod spends more time around top dead center (0 degree crank angle) due to a slower acceleration rate towards and away from TDC. A longer dwell time around top dead center makes better use of the combustion preUssure and turning the pressure into torque; a rule of thumb is that you want peak combustion pressure around 15-17 degrees after TDC. Furthermore, the combusiton pressures are higher while the crank angle is lower resulting in less side loading of the piston into the bore. Less side loading results in less friction between the piston and bore freeing up power and reducing wear. The reduced piston acceleration also improves piston ring life as the lower acceleration equals less force on the rings (remember F=ma?).

The Yamaha YZF R1 is a typical modern sports bike that revs to 12,000 rpm. Its engine has a stroke to rod length ratio of 2.12:1 which is suitable for high rpm use. This can be compared to a Nissan SR20DE engine which revs to 7700 RPM with a rod to stroke length ratio of 1.58:1

The R1 engine has a pretty tall deck height compared to the general compactness of the crankcase. In the case of the bike, the chassis is designed around the engine. With a 110.5mm rod and a 52mm stroke, the engine is tall for its displacement compared to a car engine.

We think automotive engine designers compromise rod length to try to fit engines under low hood lines of modern cars. This is one of the reasons why the SR20DE ended up with a pretty poor rod ratio for a performance motor.

Does Length Matter?

by Khiem Dinh

Khiem Dinh is an engineer for Honeywell Turbo Technologies at the time of this writing. All statements and opinions expressed by Khiem Dinh are solely those of Khiem Dinh and not reflective of Honeywell Turbo Technologies.

Someone recently asked, “Why a longer rod?” Someone else answered, “Longer dwell time.” I never really thought about it before, so I thought I’d look into it. Using some basic math, we can prove that a longer rod does indeed create a longer dwell time around top dead center.

Here's a diagram showing the geometry between the crank, connecting rod, and piston. The math only works out assuming the piston pin location is not offset. So using some basic trig, we can calculate piston position (S =A+B in this diagram) versus crank angle.

This graph shows piston position (normalized so that 0mm is BDC) vs. crank angle for 100mm and 300mm long connecting rods on an engine with an 86mm stroke. Yeah, you would never use a 300mm long conrod, but I wanted to make it easier to show the difference.

As you can see in the diagram, the piston with the longer conrod spends more time around top dead center (0 degree crank angle) due to a slower acceleration rate towards and away from TDC. A longer dwell time around top dead center makes better use of the combustion preUssure and turning the pressure into torque; a rule of thumb is that you want peak combustion pressure around 15-17 degrees after TDC. Furthermore, the combusiton pressures are higher while the crank angle is lower resulting in less side loading of the piston into the bore. Less side loading results in less friction between the piston and bore freeing up power and reducing wear. The reduced piston acceleration also improves piston ring life as the lower acceleration equals less force on the rings (remember F=ma?).

The Yamaha YZF R1 is a typical modern sports bike that revs to 12,000 rpm. Its engine has a stroke to rod length ratio of 2.12:1 which is suitable for high rpm use. This can be compared to a Nissan SR20DE engine which revs to 7700 RPM with a rod to stroke length ratio of 1.58:1

The R1 engine has a pretty tall deck height compared to the general compactness of the crankcase. In the case of the bike, the chassis is designed around the engine. With a 110.5mm rod and a 52mm stroke, the engine is tall for its displacement compared to a car engine.

We think automotive engine designers compromise rod length to try to fit engines under low hood lines of modern cars. This is one of the reasons why the SR20DE ended up with a pretty poor rod ratio for a performance motor.